Intersection tray erectors

60

TRAYS/CYCLES

PER MINUTE

THE UTMOST IN PRECISION. TRAY FOR TRAY, DAY FOR DAY.

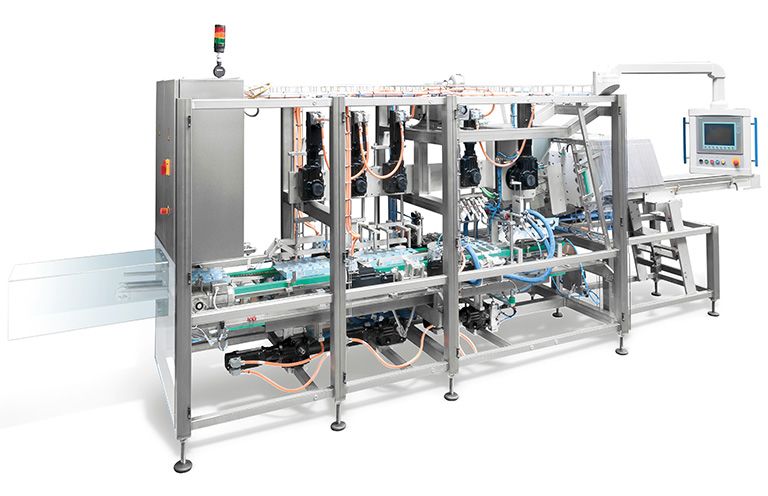

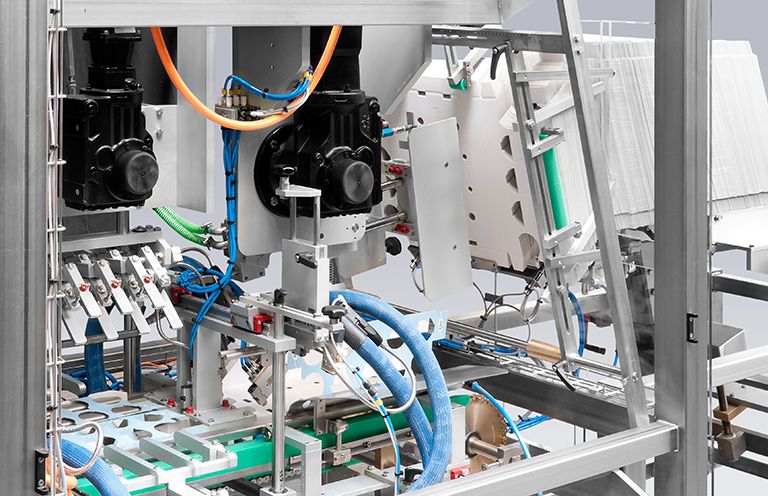

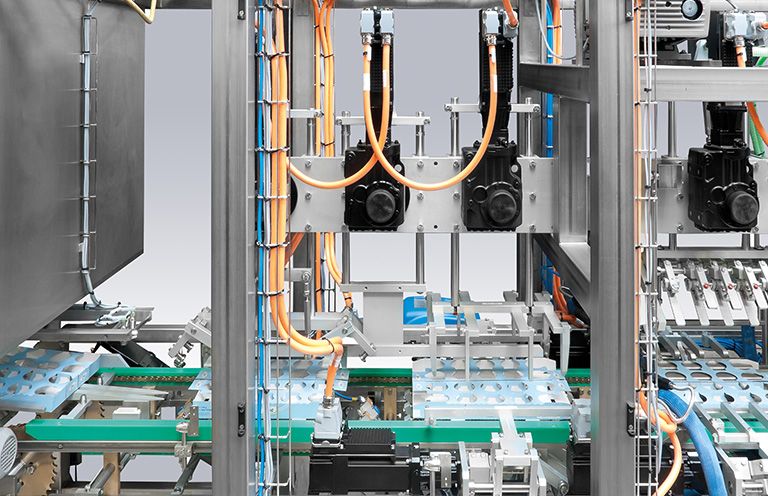

Exactly and accurately formed; with a perfectly precise repeat accuracy: This is how every user want their trays to be produced. The very best quality at a high performance. And it was precisely this requirement profile that stood at the forefront during the development of the SFS 337 Tray Erector. And we stand by it day after day. In terms this means: We only use servo drives. When it comes to the machine frames, we value maximum stability, so that they do not move even in the case of high output.

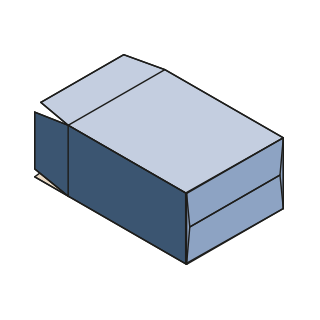

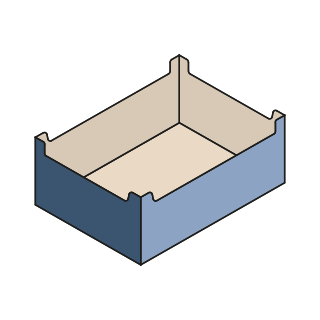

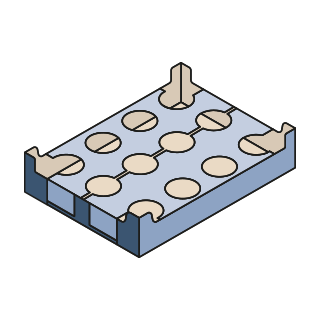

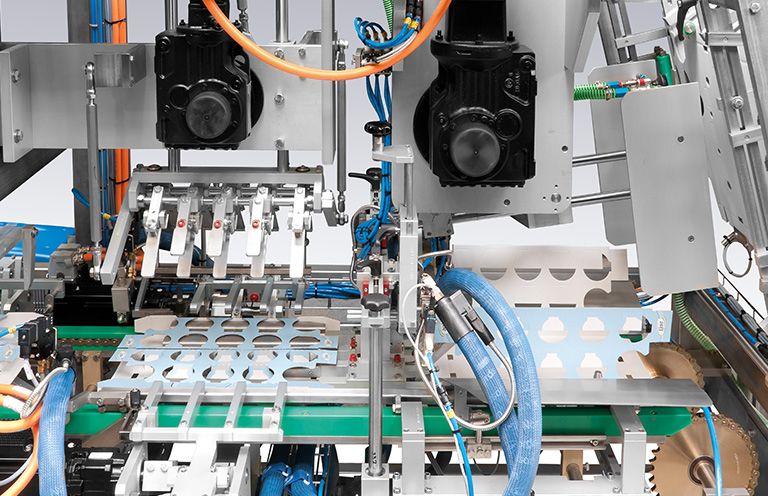

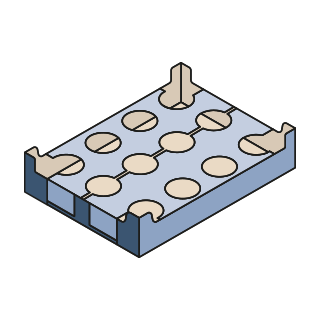

Regardless of whether the machine is handling open or intersection trays with a blank size of up to 400 x 300 mm; with this high-output tray erector, the complex folding processes are spread across several stations. The quality of this series satisfies the most demanding requirements. The increasing demand for greater flexibility has spurred the development on further. Whether erectors for trays with various footprints and several heights, divisible trays with 8 stacking corners, trays with and without center bar gluing or even with supporting flaps; the individual design is based entirely on the requirements of the customer.

INTERSECTION-

TRAY-ERECTOR

SFS 337

You need Javascript enabled to view this video.

These contents are available only after log-in. Please log-in with username and password.

We will be pleased to supply you with further information about our products.

Download data sheets and leaflets here. Have a look at the video showing the functional principle. Or feel free to get in personal contact with our team by sending an e-Mail to sales@sfs-net.de

Benefits at a glance

- Up to 60 trays/cycles per minute

- For open trays and intersection trays

- Modular design, for versions:

- with and without stacking corners

- also in divisible version

- with 8 stacking corners

- with and without center bar gluing

- with supporting flaps - Blank design from solid board to double wave

- Consistently servo-driven

- Format flexibility ensured by changeable folding tools

- Optional: Automatic loading of the blank magazine